Business

Business Areas

출처 : IAEA(국제원자력기구) / ITER Organization

Business Areas

Fusion Reactor

Since starting the fabrication and supply of Thermal Shields for the ITER (International Thermonuclear Experimental Reactor) project, our company has continued to manufacture and supply a wide range of fusion-related equipment.

-

01

Participation in the ITER Project

- Thermal Shield fabrication in 2013, delivered in 2020

-

02

Toshiba (Japan), machining and delivery of 9 sets of Coil Cases

- Received machining work order from Toshiba in 2018 and delivered completed products

-

03

Hyundai Heavy Industries, ERP Flange delivery

- Secured and delivered high-difficulty components requiring 5-axis machining

-

04

Hyundai Heavy Industries, Rack Locking Prototype

-

05

Received second Thermal Shield order from IO (France)

-

06

Received vacuum vessel order from DTT (Italy)

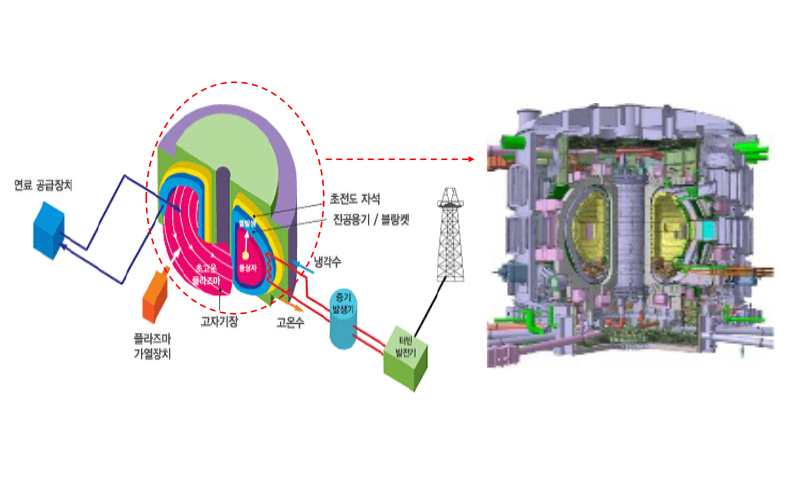

The International Thermonuclear Experimental Reactor, a global collaboration of seven nations to realize fusion reactor, the energy of the future

ITER Project (International Thermonuclear Experimental Reactor)

Also known as the Artificial Sun Project

- Participating Countries

- EU, Korea, USA, Japan, India, Russia, and China (7 nations)

- Construction Period

- Device construction (2007–2025), followed by 15 years of operation

- Total Construction Cost

- 7.11 billion EUR (approx. 20 trillion KRW)

- Capacity

- Thermal output 500 MW

- Location

- Cadarache, France

- Features

-

- Each participating nation manufactures and supplies its allocated components for final on-site assembly

- Thermal Shield fabrication was carried out 100% by Korea (exclusive technology held by our company, 2013–2020)

- Abundant fuel, extremely high efficiency, high safety, and environmentally friendly

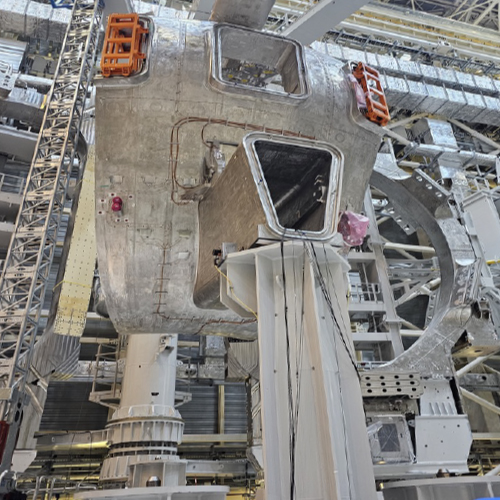

ITER Installation Site and Thermal Shield Contract Signing (2023.07.10)

- Scale

- Experimental reactor < Demonstration reactor < Commercial reactor

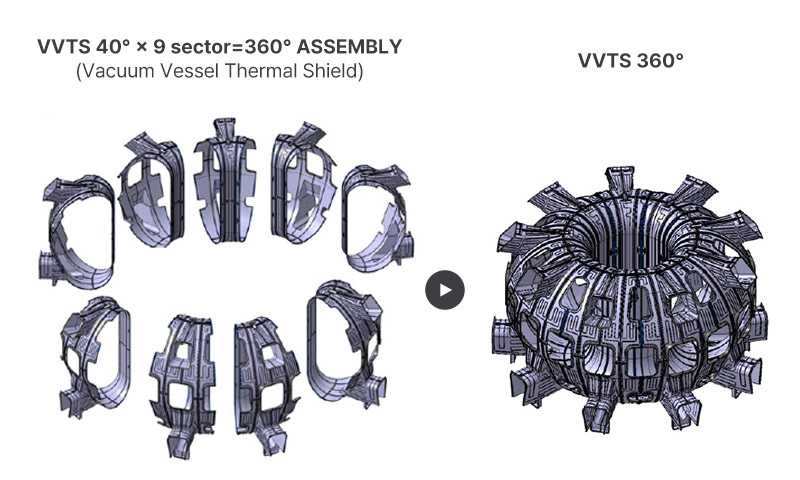

Thermal Shield and Coil Case, the major fusion reactor components supplied by our company

Thermal Shield

- Client

- National Fusion Research Institute / SFA

- Project

- Thermal Shield fabrication (9 sectors)

- Production Period

- 2013.10–2020.12

- Scope of Supply

- Mockup fabrication and main unit (production design–welding–machining–assembly)

- Features

-

- Among all participating nations in the ITER Project, Korea was the only country to fabricate and supply the Thermal Shield, requiring four years of R&D preparation

- Using 1,000 tons of stainless steel, the units were welded, machined, and assembled, then finished with silver (Ag) coating and delivered to France

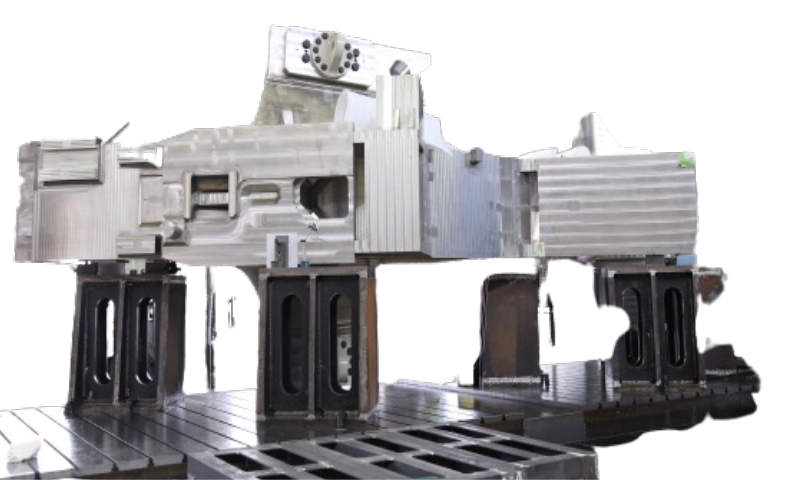

Coil Case

- Client

- Toshiba (Japan)

- Project

- Coil Case machining

- Production Period

- 2017.10–2019.12

- Features

-

- One of Japan’s supplied components for the ITER Project, consisting of 9 sets requiring advanced 5-axis machining technology